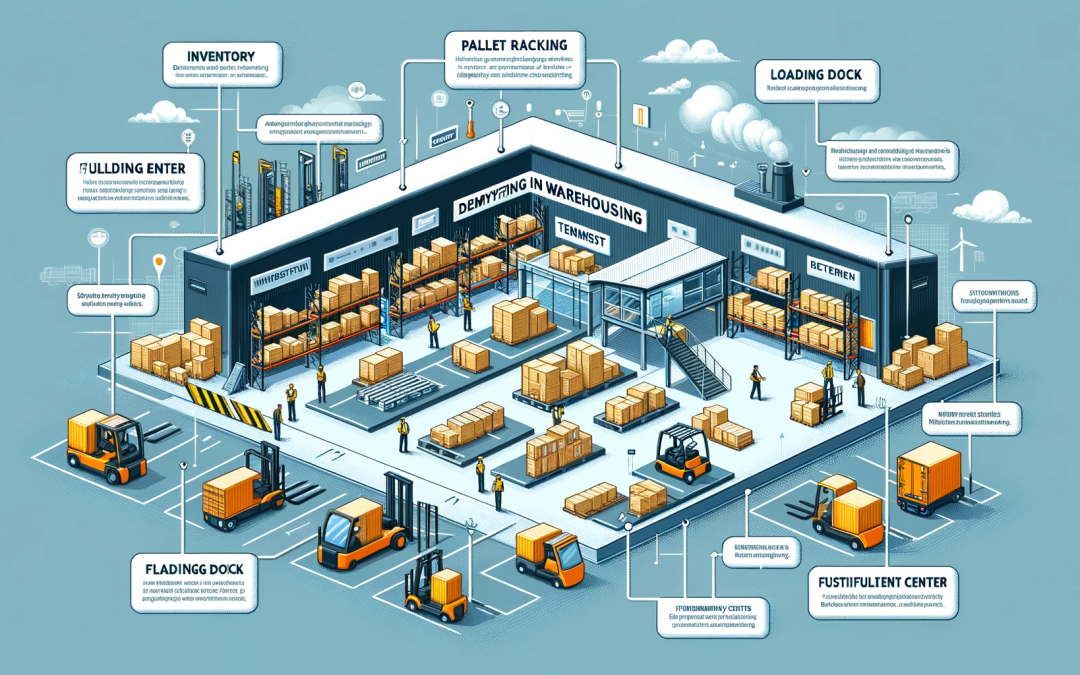

The world of warehousing is rich with specialized language and acronyms that can be bewildering to newcomers and seasoned professionals alike. Understanding this jargon is essential for effective communication within the supply chain. Whether you’re a logistics manager, warehouse worker, or a business owner, grasping these terms will enhance your operational efficiency and help you navigate the complex landscape of warehousing. Today, we’ll unpack some of the most commonly used warehousing terms to help you become fluent in the language of logistics.

Understanding the Basics: 3PL, Backhaul, and Cross-Docking

Let’s start with Third-Party Logistics (3PL). This refers to the outsourcing of logistics operations, including warehousing, transportation, and fulfillment services, to a third-party provider. By leveraging the expertise of 3PLs, businesses can focus on their core competencies while ensuring efficient logistics management.

Another term you might encounter is Backhaul, which can be a cost-saving opportunity for transportation. It involves the return journey of a transport vehicle after delivering goods to its destination. Instead of returning empty, the vehicle carries a new load, maximizing efficiency and reducing transportation costs.

Cross-docking is a practice that minimizes storage time in the warehousing process. Products are unloaded from an inbound vehicle and immediately loaded onto an outbound vehicle, streamlining the distribution process and reducing handling costs.

Streamlining Inventory Management: FIFO and Just in Time (JIT)

Effective inventory management is the backbone of warehousing. First in, First out (FIFO) is a method that ensures the oldest inventory is shipped out first, which is particularly important for perishable goods. On the other hand, the Just in Time (JIT) strategy aligns inventory orders with production schedules and customer demands, reducing the holding costs of inventory.

Embracing Automation: Lights-Out Warehouse

As technology advances, so does the warehousing industry. A Lights-Out Warehouse is a fully automated facility that operates with little to no human intervention. This futuristic approach relies on robotics and artificial intelligence to manage and move inventory, offering a glimpse into the future of warehousing.

Dive Deeper Into Warehousing Knowledge

These terms are just the tip of the iceberg when it comes to warehousing vocabulary. To truly master the language, one must delve into the details. Our comprehensive guide offers in-depth definitions and examples for a wide array of warehousing terms, from A to Z. Whether you’re training new staff or brushing up on the latest logistics trends, this glossary is an indispensable resource.

| TERM | DEFINITION | ADDITIONAL SOURCES |

| 3PL | The engagement of external companies to execute logistics activities traditionally done within the organization itself. | Investopedia: Third-Party Logistics (3PL) |

| Backhaul | The act of a transport vehicle returning to its origin after reaching its destination, particularly in the context of goods or equipment transportation. | Logistics Bureau: Backhauling in Logistics |

| Back order | An order for a product that is temporarily out of stock and cannot be fulfilled immediately. | Shopify: Managing Back Orders |

| Barcoding | Utilizing barcodes and scanners for inventory management and tracking in a warehouse. | Barcoding, Inc.: Barcode Basics |

| Batch Picking | A warehouse order picking method where multiple orders are collected simultaneously to boost efficiency. | 6 River Systems: Batch Picking Explained |

| Bill of Lading (BOL) | A document from a carrier to a shipper detailing the goods’ type, quantity, and destination in a shipment. | Shipping Solutions: Bill of Lading Guide |

| Cantilever Rack | A storage rack design featuring extending arms from a single column, suited for lengthy or bulky items. | UNARCO Pallet Rack: Cantilever Rack Basics |

| Cold Storage | Warehouses with temperature control for storing perishable items like food, pharmaceuticals, etc. | International Warehouse Logistics Association: Cold Storage |

| Cross-docking | A logistics practice where goods are directly transferred from supplier or production to customer or retail with minimal handling or storage. | Inbound Logistics: Cross-docking 101 |

| Dimensional Weight (DIM) | A shipping cost calculation based on estimated weight derived from a package’s dimensions. | FedEx: Dimensional Weight |

| Dispatching | The process of organizing and managing the deployment of vehicles for goods delivery. | Fleet Complete: Dispatching Basics |

| Distribution Centre | A facility for storing products before redistributing them to retailers, wholesalers, or consumers. | Warehouse Anywhere: Distribution Centre Strategies |

| Drop Trailer | A transport trailer left at a location for loading/unloading, to be collected later. | SmartWay Transport: Drop Trailer Program |

| Dry Storage | Non-temperature-controlled sections in a warehouse for non-perishable goods. | Global Cold Chain Alliance: Dry Storage |

| Estimated Time of Arrival (ETA) | The predicted time of arrival for a shipment or vehicle at its destination. | FourKites: Predictive ETA |

| Estimated Time of Departure (ETD) | The anticipated time a vehicle or ship will depart from its origin, often used by warehouses to schedule when delivery vehicles will leave the loading bay. | Learn more |

| Estimated Time of Delivery (ETD) | The predicted time that goods will reach their final destination, provided by suppliers to inform receiving clerks of incoming inventory. | Learn more |

| FIFO | An inventory rotation system where the oldest stock is shipped out first, commonly used in food warehousing to manage product expiration dates. | Learn more |

| Forward-pick location | A strategic storage spot designed for quick access to frequently ordered small quantities, enhancing picking efficiency and customer order turnaround. | Learn more |

| Gaylord Box | A large-sized bulk container that fits on a pallet, widely utilized for the transportation and storage of varied goods in the logistics sector. | Learn more |

| Inventory Management Systems | Software that monitors the flow and storage of goods, optimizing inventory levels and minimizing backorders and excess stock. | Learn more |

| Just in Time (JIT) | A lean inventory strategy where goods are ordered and received just in time for assembly or shipping, minimizing storage costs and avoiding excess stock. | Learn more |

| Last Mile Delivery | The final step in the supply chain, transporting goods from a warehouse or distribution centre to the customer’s location. | Learn more |

| Lead Time | The duration required to complete a process in the supply chain, from order placement to final delivery, including all intermediate steps. | Learn more |

| Less Than Truckload (LTL) | Freight shipping for goods that weigh over 150 pounds but less than a full truckload, allowing multiple shippers to share space and costs. | Learn more |

| Lights-Out Warehouse | A fully automated warehouse where machines and robots handle product storage and movement, eliminating the need for human labour. | Learn more |

| Material Handling Equipment (MHE) | The assortment of tools and machinery, such as forklifts and conveyor belts, used to facilitate the movement and storage of products. | Learn more |

| Order Fulfilment | The entire process from receipt of an online order to the delivery at the customer’s doorstep, encompassing all stages of handling and shipping. | Learn more |

| Order Picking | The activity where workers retrieve the exact items required to fulfil individual customer orders. | Learn more |

| Packing | The process of preparing purchased goods for shipment, including boxing and preparing them for transportation. | Learn more |

| Packing List | A document listing all the contents of a particular shipment, used for tracking and verification purposes. | Export.gov: Packing List Essentials |

| Pallet | A portable platform, usually made of wood, that facilitates the moving and storage of large items or quantities and is compatible with handling equipment. | National Wooden Pallet & Container Association: Pallet Basics |

| Pallet Racking | Storage systems designed to support pallets, enhancing warehouse organization and storage density. | Material Handling Industry: Pallet Rack Basics |

| Pick and Pack | The integrated warehouse processes of selecting items (picking) and preparing them for dispatch (packing). | American Supply Association: Pick and Pack Methods |

| Pick List | A detailed inventory that directs warehouse workers to the items that need to be retrieved to fulfil customer orders. | APICS: Pick List Optimization |

| Picking | The operation where workers gather items from storage to fulfil customer purchases. | Warehouse Management Systems Guide: Picking Strategies |

| Purchase Order (PO) | A formal request from a buyer to a seller for the supply of goods, prompting restocking activities in warehouses. | Purchasing & Procurement Centre: Purchase Orders Explained |

| Put-away | The warehouse activity of moving received inventory to its designated storage location. | Logistics Bureau: Put-away Process |

| RFID | A technology that uses radio waves for data transfer and tracking, deployed in warehouses to monitor inventory movement. | RFID Journal: Warehouse RFID Applications |

| Receiving | The initial warehouse process where incoming goods are checked and documented by a receiving clerk. | Warehouse Management Guide: Understanding Receiving Process |

| Replenishment | The process of adding inventory, whether it’s restocking returned items or moving items to a primary picking location. | Inventory Management Review: Inventory Replenishment Methods |

| Reverse logistics | The flow of returned goods back to the retailer or origin point for restocking or disposal. | Reverse Logistics Association: Guide to Reverse Logistics |

| Safety stock | Additional inventory kept to prevent stockouts due to unexpected demand or supply delays. | Supply Chain Dive: Managing Safety Stock |

| Shipping manifest | A detailed list that records all items loaded onto a transport vehicle for shipment. | Transport Insights: Shipping Manifest Importance |

| SKU | Stock-keeping unit (see stock-keeping unit for definition). | Retail Operations: SKU Management |

| Supply chain | The entirety of processes involved in producing and distributing products, from production to final delivery. | Supply Chain Academy: Supply Chain Fundamentals |

| Stock-keeping unit (SKU) | A unique identifier for inventory tracking assigned by retailers, distinct from universal product codes (UPCs). | National Retail Federation: SKU vs UPC |

| Stockout | The absence of inventory for a particular item, often indicating a pause in product availability or discontinuation. | Logistics Bureau: How to Prevent Stockouts |

| Third-party logistics (3PL) | A logistics service provider that offers comprehensive services beyond warehousing, including inventory management and delivery. | 3PL Central: The Rise of Third-Party Logistics |

| Universal Product Code (UPC) | A globally recognized barcode with a 12-digit numerical code assigned to products for identification. | GS1 US: Understanding UPCs |

| UPC | Universal Product Code (see Universal Product Code for definition). | GS1 US: UPC and Barcode Basics |

| WMS | Warehouse management system (see warehouse management system for definition). | Software Connect: WMS Software Features |

| Warehouse management system (WMS) | A software solution that supports the management and operations of a warehouse, accessible from various devices. | Capterra: Warehouse Management System Features |

| Zone picking | A method of order picking where each worker is assigned a specific zone to pick from, consolidating items before shipping. | Material Handling & Logistics: Zone Picking Explained |

Stay ahead in the logistics game by familiarizing yourself with these and many other warehousing terms. Knowledge is power, and in the fast-paced world of warehousing and logistics, it’s the key to unlocking efficiency and innovation.

This blog post serves as an introduction to the more comprehensive document that delves into each term in detail. If you’re interested in a specific section of the document or a selection of terms for a deeper dive, let me know and I can provide further tailored content.

Please contact us to know how we can asssist.

rohit@rccoAdvisory.com